Keeping Medical Device & Diagnostics Companies Compliant when “Business as Usual” Falls Short

New regulations require new operating models for medical device & diagnostics companies

When it comes to adhering to medical device regulations, companies must be wary of “business-as-usual” practices. The processes that have worked for decades are fast becoming inadequate.

A manufacturer of endoscopes recently learned this lesson the hard way. The company enjoyed a robust business that included selling devices in a number of countries. Its sales to China were particularly strong, and, in fact, had become a significant revenue stream over the previous five years.

But that came to an abrupt end last year when the manufacturer’s director of regulatory affairs received a letter from the Chinese Ministry of Justice ordering the company to stop selling endoscopes in the country.

Why? The manufacturer had failed to abide by the Ministry’s Order No. 650, a new regulation that, in part, now requires submission of self-test reports or independently conducted test reports. Adding insult to injury, these reports already existed to meet requirements in other countries.

The requirement was not all that onerous, but it was implemented quickly by Chinese authorities. The endoscope manufacturer was slow to react and share key data across the organization, and therefore faced an uphill battle to become compliant. As a result, the company was staring at a significant revenue shortfall for the year.

Issues like these will no doubt become more common as regulators are rethinking how they regulate medical devices in order to address changes in technology, such as software, while also protecting public health.

For example, the US Food and Drug Administration (FDA) reorganized the Center for Devices and Radiological Health to better adapt to future regulatory needs. Regulatory changes like European Union Medical Device Regulation (EU MDR) are always on the horizon.

But these new regulatory mandates are not the only factors driving the need for improved processes and infrastructure within the medical device industry. Medtech companies are facing a growing need to share all operations data across the organization to improve efficiency as well as compliance.

“When problems arise, companies often try to categorize them as either a business risk or a compliance risk. But since we work in an extremely regulated industry, problems that affect quality or compliance can quickly become both,” says industry consultant and RAPS board member Michael Morton. “Quite often it becomes something the entire business is looking at.”

“When problems arise, companies often try to categorize them as either a business risk or a compliance risk. But since we work in an extremely regulated industry, problems that affect quality or compliance can quickly become both” – Michael Morton, Board Member, RAPS

Meanwhile, emerging and fast-moving technological developments have introduced their own set of risks and myriad regulatory hurdles. Demystifying new regulations and reacting to them in an agile manner is top of mind for medical device manufacturers.

It is giving rise to a new normal that requires integrated systems across the entire product life cycle, as well as more touchpoints and access to real-time data changes.

“Manual or paper-based methods for developing and maintaining high-quality medical devices are ill-suited for the real-time demands of today’s data-driven and global health care system,” says Roxane Bonner, QA/RA Program Director at Roche Diagnostics.

“Manual or paper-based methods for developing and maintaining high-quality medical devices are ill-suited for the real-time demands of today’s data-driven and global health care system” – Roxane Bonner, QA/RA Program Director, Roche Diagnostics

Recognizing The Need To Adapt

A report and survey of medical device manufacturers produced by Gens and Associates revealed that medical device and diagnostic manufacturers have an increased focus on implementing regulatory information management (RIM) systems.

The report acknowledged that regulatory functions are rapidly evolving due to a desire to improve organizational productivity and efficiency; investments in system, process and data quality improvements; a desire to connect key regulatory capabilities with other enterprise information systems;and increasing complexity in health authority regulations.

The survey — which involved 69 medical device and diagnostics companies — found that:

- Most device manufacturers are looking to improve cross-functional information flows to benefit the full lifecycle management processes.

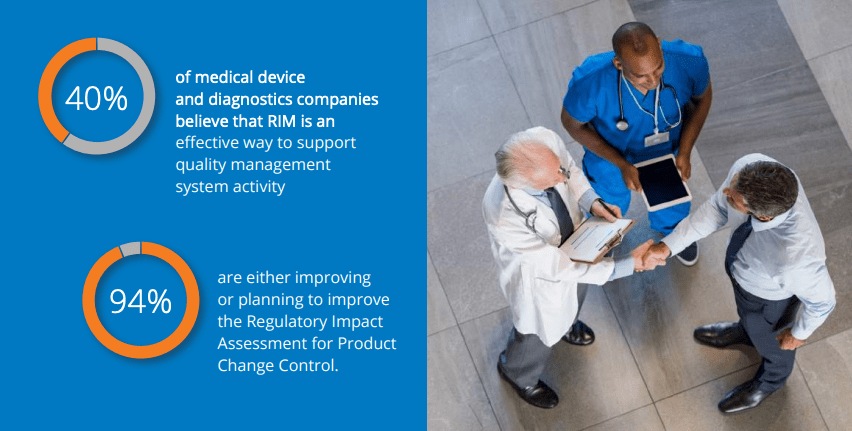

- Nearly four in 10 believe that RIM is an effective way to support quality management system activity; almost half are working to facilitate this connection.

- 94% are either improving or planning to improve the Regulatory Impact Assessment for Product Change Control.

- 11% had an ERP-to-RIM connection in 2018, and this was expected to increase to 40% by 2020.

The survey also revealed that six in 10 device manufacturers had a dedicated RIM group in 2018 Not surprisingly, these companies tended to have more efficient data management, product registration, health authority commitments, labeling, supply release and submission document management.

They also experienced reduced data remediation costs, improved submission forecasting, reduced operating costs, and simplified affiliate interactions.

In short, these organizations recognized early on that their legacy platforms were not going to be able to be adaptable to provide the agile environment needed to address new requirements with efficiency.

Simply layering on a new piece of software, such as Excel or SharePoint, would not be sufficient. Unless they adapted, they risked noncompliance, diminished quality, higher costs and, ultimately, decreased revenue.

A Transformation Journey: Roche Diagnostics

Roche Diagnostics was one of the companies that recognized the emergence of this new normal early on. Its regulatory team realized that it needed a system that could change quickly as processes and regulations evolve over time.The company’s leaders decided to look for a RIM system that could track global registrations, submissions and health authority questions in order to drive business objectives and operational efficiencies worldwide.

They identified requirements and recognized they needed a RIM solution that could:

Provide Full Visibility Into Global Submissions.

The global product registration process is a major challenge that requires planning, document management and submissions tracking. These activities utilize large numbers of documents and span complicated review and approval life cycles. Use of localized independent methods and tools to manage this work limits visibility of registration activities, leads to inefficiencies, and has the potential for compliance risks.

A high-quality centralized RIM solution should be able to break down the registration process into trackable work packets and approval cycles for each part of the submission. It should provide visibility and flexibility to accelerate the submission process.

Work could be assigned to specific individuals and use of due dates could keep the work on track. Users could extract specific submission information into customized reports giving them clear visibility to registration status in each country.

These capabilities have the potential to achieve consistency across all regions, ensure global compliance and bolster confidence in their global portfolio.

Streamline Global Registrations and Enable Speedier Responses.

Losing at least some global registrations is often seen as part of doing business, with device manufacturers building this loss into their estimates. They may use an Excel tracker or a point solution with limited functionality and an ad hoc configuration, soon finding that submissions are lost because a reminder sits on one person’s Outlook calendar.

Addressing new regulations would require a solution that allows for a single source of truth in order to:

- Improve quality by reducing duplicate data and discrepancies

- Enable complete visibility of the global product portfolio

- Pave the way for a unified, end-to-end submission process

“Another driver in our RIMS strategy is to be able to trend and assess registration data and respond quickly to changes we see emerging in the global regulatory landscape,” said Lauren Buchholz, Director of Regulatory Affairs for Roche Diagnostics.

“This is a significant advancement that potentially benefits many areas of our business. Without this capability, we could run the risk of developing product that may not meet registration requirements in some markets.”

“Another driver in our RIMS strategy is to be able to trend and assess registration data and respond quickly to changes we see emerging in the global regulatory landscape” – Lauren Buchholz, Director of Regulatory Affairs, Roche Diagnostics

Facilitate a Divide-and-Conquer Approach to Health Authority Questions.

It takes significant time to pull together answers to health authority questions, especially without an automated platform. The regulatory department hunts down answers from experts and tracks them manually, which is a logistical nightmare that can hinder speed to market.

A good RIM solution tracks each application question, assigns it to the appropriate expert, and tracks the status. The regulatory department is then able to employ a divide-and-conquer strategy across teams in a way that is fully auditable and pulls answers quickly. This speed can help get products to market faster.

Success in Action

Roche was becoming increasingly concerned that a business-as-usual approach was putting it in a more vulnerable position as the last 10 years have brought an explosion in new regulatory requirements. Meanwhile, advanced technology for diagnostics brings its own set of challenges with regard to registration requirements.

At a certain point, it becomes impossible to successfully manage these challenges with outdated tools and point solutions. To address these challenges, Roche found success with the Veeva Vault RIM Suite, which:

Provides Better Visibility and Greater Agility.

Roche has >90,000 licenses worldwide. Prior to using the Vault RIM Suite, Roche had suboptimal methods for tracking where their products were registered.

Each country affiliate office had their own local registration information, but visibility at the regional and corporate levels required a number of manual tasks, including compiling data from multiple Excel tables. The RIM solution removes this burden and establishes a single source of truth.

Provides More Rapid Feedback on Changing Registration Needs and Facilitates Real-time KPI Development.

Prior to implementing the Vault RIM Suite, Roche’s regulatory managers worried that manual processes might be compromising business decisions. Moreover, registration processes in some countries are very complex, potentially leading to missed business opportunities.

The RIM solution has improved Roche’s ability to track and understand the registration requirements in all the countries, and to adapt key performance indicators in real time to optimize the registration process in each country, and thus maximize revenue across the entire portfolio.

Gets Products to Market Faster.

The company’s old way of managing regulatory documents fostered a reactive way of working. Personnel who supplied registration documents to the affiliates didn’t do so until the affiliates requested them.

Now with the Vault RIM Suite, affiliates post their future submission dates and the documents are proactively made available, thus eliminating the cycle of request and wait, which improves speed to market.

Solved Human Resources Constraints.

Like most organizations, Roche’s regulatory professionals are being asked to respond to new regulatory realities, sometimes without increasing headcount.

Because Veeva Vault RIM provides more proactive and efficient ways of working, the regulatory division is able to provide the same or better level of service to the affiliates and health authorities without increased staffing costs that would be required in the absence of an advanced technology platform.

Moreover, the old, manual processes required a level of training that is no longer sustainable. With this barrier removed, employees are able to focus more exclusively on revenue opportunities.

Of course, it takes more than just an improved technology platform to truly transform a regulatory operations model. The key, Roche says, is to harmonize business processes before implementing any new technology.

By simultaneously implementing a formal change management process, device and diagnostic companies can maximize a high-quality RIM system to protect their ability to operate and succeed in an increasingly complex global regulatory environment.

Medical device and diagnostics companies face tightening regulations as health authorities increase oversight and implement strict compliance timelines. Some will resist change, ignore requirements or delegate responsibility inappropriately.

For these companies, a negative outcome will trigger the need to adapt. It is far better to be proactive, anticipate change and implement a solution to avoid these negative consequences and ensure a positive, proactive and compliant business environment.