Industry Report

4 Insights on PV Transformation

PV experts share insights on key safety trends: unified, connected safety; AI and automation; bringing safety in-house; reducing risk and improving efficiency.

How Biopharmas are Unlocking the Strategic Value of Safety Data

Pharmacovigilance (PV) teams are pressured to deliver sustainable, increased operational efficiency while unlocking the strategic value of safety data.

To meet these demands, the industry is undergoing a critical shift: moving beyond manual and siloed compliance-focused systems and processes toward simplification and automation with end-to-end digital platforms. This transformation will enable companies to more easily manage growing case volume and complexity, as well as provide better insights from safety information.

Here are four insights from recent industry events on the top challenges PV teams are focused on:

| |

|

|

|

SAFETY INSIGHT 1

A unified, connected safety platform drives efficiency and data quality, improving global to local collaboration

KEY TAKEAWAYS

-

PV teams are consolidating technology systems and eliminating data silos

-

A single, connected global safety database enables speed and compliance

-

Automating data flow reduces duplication and reconciliation

MSD was managing over 30 siloed technology systems across its business, which created data siloes, required reconciliation, and made upgrades extremely costly and disruptive. The move to Veeva's connected safety platform was driven by the need to simplify workflows and improve data quality and operational efficiency.

Since go-live, MSD has removed 10 systems from its technology infrastructure while maintaining its global compliance goals. A primary achievement was unifying its global and Japan databases, enabling direct submissions to PMDA and other health authorities from a single system.

"One thing we are particularly happy about is removing that duplicate data entry with Veeva Connections,” said Jeroen van Doorn, director of business system management and integration. “If someone is already entering the data in a lower system [i.e., another Vault], why would you re-enter that data in your own system? And we can already see with the connections we have... that it's working. It just works."

See how MSD is reimagining safety with simplified and connected technologies.

"If someone is already entering the data in a lower system [i.e., another Vault], why would you re-enter that data in your own system? And we can already see with the connections we have... that it's working. It just works."

Novo Nordisk said it was focused on creating one global safety database, which will similarly eliminate separate local intake systems in Japan, China, and the U.S, said Ellen Englev, senior director of PV technology. This new structure is designed to provide real-time global oversight for headquarters while also giving affiliates, for the first time, a clear view of their local case status.

Novo Nordisk is also leveraging its existing Veeva ecosystem by implementing Veeva Connections for Safety and its Regulatory, Quality, and Clinical (EDC) Vaults. This strategy is central to achieving efficiency by automating data flow, eliminating custom integrations, and reducing manual reconciliation efforts.

Learn how Novo Nordisk is driving efficiency with a global, connected safety solution.

Establishing shared data on a single, unified platform also supports data-driven decision-making and proactive risk management. As one senior director of PV management explained, the disconnected legacy environment hindered proactive data use, and a key driver for moving to a single platform was to implement tools specifically for signal detection and risk management.

SAFETY INSIGHT 2

Automation and safety-specific agentic AI is helping elevate PV from operations to strategic impact

KEY TAKEAWAYS

-

Industry-specific agentic AI will drive innovation and productivity in PV

-

AI requires a strong data foundation as well as focus on people, process, and technology

-

Promising PV uses cases include case intake, narrative generation, and translations

AI was a major focus at World Drug Safety Congresses in Amsterdam and Boston, with its promise for innovation and productivity gains. In PV, the buzz is focused on substantial efficiency gains from automating high-volume, manual tasks that are prone to human error and inconsistency, including processes like case intake, narrative generation, and translations.

Many companies are realizing that simplification and standardization are the best accelerators for AI adoption. Companies will need to invest in people and processes to get the most value from AI projects, including new skill sets, behavior and process change, and resource reallocation.

“I think one area where AI will help is case intake, because we get a lot of unstructured data,” said Aniket Agarwal, the director of patient safety data operations and analytics at Sandoz. “E2B data is easy to ingest because of the structure. But 60% of our data is not coming in that way. I think this is where AI can help structure that information so that you can use downstream automation to process it efficiently.”

"E2B data is easy to ingest because of the structure. But 60% of our data is not coming in that way. I think this is where AI can help structure that information so that you can use downstream automation to process it efficiently.”

Hear how the right data and technology foundation enables automation and AI.

For example, Veeva’s Case Intake Agent helps this process by ingesting data and documents from emails or upstream systems. The agent can review the document, extract relevant case information, and identify anomalies. Case processors can then directly view source information to verify accuracy and completeness, and quickly identify issues that require correction or follow up, improving speed, accuracy, and efficiency.

SAFETY INSIGHT 3

In-house safety systems reduce costs, improve real-time data visibility, and strengthen CRO partnerships

KEY TAKEAWAYS

-

Outsourcing is common in PV, but can create inefficiency, high costs, and compliance risk

-

Bringing safety systems in-house improves data quality and real-time visibility

-

In-house safety can control and even significantly reduce costs

While outsourcing is commonplace in PV, especially for smaller companies, many biotechs are recognizing the strategic value of an in-house approach to safety. One small U.S.-based biotech struggled with inconsistent data, fragmented processes, and “tons of rework” after outsourcing various safety activities to CROs.

Now, a key part of its safety strategy is mandating that all partners, including CROs, use its internal Veeva system. This eliminates the need for data transfer agreements, stops CRO "line item fees" for simple reports, and creates a single source of safety data. This centralized approach, which extends beyond PV to other functions, also improves inspection-readiness and provides a complete, real-time view of safety data across all programs.

"We've saved millions of dollars by bringing our EDC and all these systems in house.”

"When you look at the number of extra meetings, program management time, extra reports — we've saved millions of dollars by bringing our EDC and all these systems in-house,” said the company’s chief medical officer.

Learn more about scaling PV operations with connected safety.

EU-based biotech Camurus faced similar issues with their fully outsourced model. The team had no direct access to its safety database and faced challenges with compliance and data quality.

“I couldn't get access to the data, I didn't have access to the safety database,” said Johanna Strandell, director of patient safety and QPPV. “For example, I couldn't retrieve the number of reports for a certain event.”

Camurus opted to bring its PV activities back in house. Strandell described the results as transformative, including achieving nearly 100% compliance for its PV activities. The company was able to keep costs neutral even with a significant increase in case volume.

Discover how Camurus improved control, data quality, compliance, and oversight.

SAFETY INSIGHT 4

Centralizing and scaling safety content and processes on a validated platform improves collaboration, reduces risk

KEY TAKEAWAYS

-

Managing safety documents and data in disparate systems creates compliance risks

-

A centralized process improves global-to-local collaboration on key safety documents

-

A validated system for PV content provides clear audit trails for inspection readiness

Small biopharmas often manage key safety documents like the PV system master file (PSMF), PV agreements (PVAs), and risk management plans in general-purpose, non-validated content management applications. While convenient in early stages, these tools are not designed for regulated PV processes — creating risks with no clear audit trails or validation documentation. For global companies, or companies with future global aspirations, this approach creates oversight issues and inefficiencies collaborating across regional/local teams, partners, or affiliates.

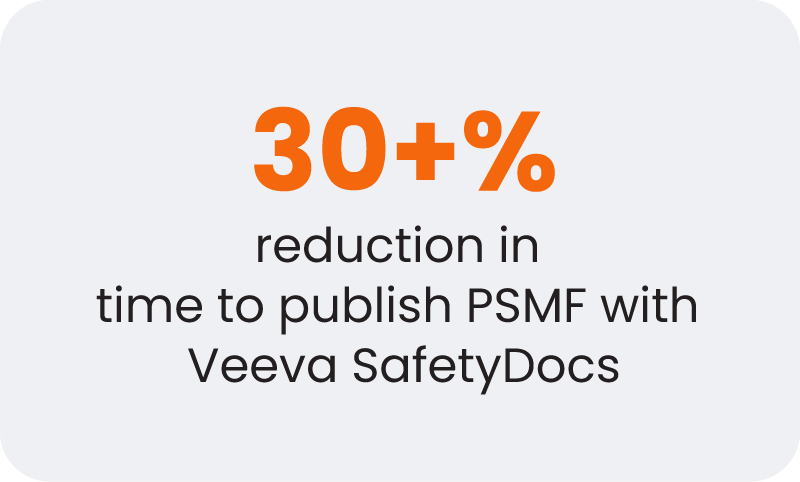

A small EU-based biopharma modernized its approach to managing safety documents and processes with Veeva SafetyDocs. Leveraging a modular approach to PSMF management, the biopharma can easily reuse global content across regions and maintain its local PSMFs for the UK and China. By harmonizing global and local PSMF management, local affiliates are able to quickly identify the latest approved content, improving inspection readiness.

Explore how to simplify PSMF management and improve global QPPV oversight.

A U.S.-based biopharma took a similar approach when it needed a scalable, centralized approach during a high-growth phase. The company wanted to centrally manage PVAs and due diligence for mergers and acquisitions. Veeva SafetyDocs provides the company with a single source of truth, enabling faster decision-making, demonstrated compliance for inspections, and the scalability needed to "handle higher volume of work" as the company expands.

"Previously, it took hours to publish a PSMF. Now, I can produce a merged PDF that contains all of the documents in the correct format in less than 30 minutes."

“This is going to help us to operate with better operational efficiency," said the head of global regulatory affairs and drug safety alliance management.

Hear how to build a culture of compliance excellence.

Stay on top of the latest trends in PV transformation

-

Read the Safety Newsletter

-

Subscribe to the Safety [R]Evolution podcast

-

Connect in person at Veeva R&D and Quality Summit in Copenhagen